Floating shelves have increased in popularity in kitchen and living area designs to replace cabinets and create a more open concept layout. Many shelf designs were originally manufactured using thick solid wood components, but there are other options which have proven beneficial for a variety of reasons. Solid wood floating shelves can be excessively heavy and difficult to mount to certain wall types. Therefore, hollow core designs using ¾ or one-inch material can be beneficial in many ways. There is also a growing trend in stairs and railings to manufacture hollow core stair treads rather than large 4 to 5-inch-thick wood treads, to be mounted on metal stair stringer assemblies.

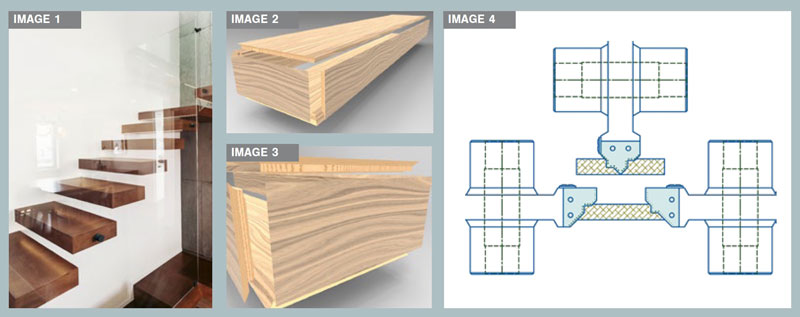

Image 1 shows an example of a creative stair assembly design incorporating metal, glass, and thick wood, to produce a contemporary style staircase. Thick wooden stair treads can be mounted on metal stair stringers from below or mounted from one side creating a floating stair design. Traditionally wooden treads are manufactured from laminated wood or solid wood components. However, a new construction method utilizing lock-mitre joinery has emerged in stair tread production as well as floating shelves.

Images 2 + 3 show how parts assemble to create a hollow box, using ¾ to 1.25 inch solid wood or wood composite panel products.

Benefits of box treads

Normally solid wood stair treads have exposed end grain, when mounted on an open stair stringer. Exposed end-grain is not an issue for rustic style products, but contemporary designers are always looking for ways to refine interior designs with more modern components. Box-tread designs allow for detailed grain matching of various wood species and wood composite products.

There are material cost savings realized by producing treads in a box formation, rather than 4 or 5-inch-thick solid wood components. Box treads do require more extensive machining processes and added labour to assemble, so the final cost of the product may be higher in some cases.

However, most customers demanding these types of products, are generally more interested in functionality and style, rather than cost. The final installation process can also be optimized by combining box tread designs with metal stair stringers. The treads can be mounted on the top of metal stair stringer, or designed to hold treads from one end to provide a floating stairway appearance. Metal support systems for floating stairs are highly technical to design and produce from a metal working perspective, but box treads designs do provide practical benefits when manufactured to assemble with metal stringers. Box treads have a hollow core which allows the wood tread to slide over metal structures from one end, to provide the most stable design. Obviously, the tread needs to be manufactured with one end open to allow metal fixture to slide inside, but this can be easily done using lock-mitred corners.

Benefits of hollow floating shelves

Large solid wood shelves can be excessively heavy and require extra large wall fastening systems, which are costly and require adequate wall strength to holder fastener and shelves safely. In some cases, particularly in renovation situations, it can be impossible to fasten heavy shelves accurately and safely.

Hollow core shelves can be 50 to 100 per cent lighter, which provides substantial benefits and flexibility for design and installation.

Under shelf lighting has become increasingly popular, but can be very tedious to install into solid wood shelves as there is no cavity to run wires. Hollow core shelves allow wires to be hidden easily inside the shelf resulting in more efficient installation. Grain and colour matching is critical in any interior home finishes, especially in the high traffic kitchen and staircase areas of houses. Panel products are most commonly used in kitchen manufacturing and can be difficult to match perfectly to solid wood components as stain and finish quality varies. Therefore, using panel products for all components is the preferred method to ensure consistent visual appeal of all home finishes.

Lock-mitred corners

Image 4 illustrates a lock mitre profile with a 90.5-degree angle and step joinery to locate the angled parts accurately. This system is commonly used in case goods, architectural millwork, and column production, but has recently found a place in stair tread production. Lock mitred corners provide the greatest level of accuracy, joint stability, and assembly convenience. Simple 45-degree components without the lock-mitre, are generally tedious to assemble, and do not provide the same level of stability and joint quality. The greatest challenge in lock miter production, is machining accuracy to produce high quality joinery. Even the slightest variation in angle accuracy, will prevent the components from assembling properly. It is critical the outside corners close tightly to avoid any gaps or misalignment, which are difficult to correct once machining is complete.

Tooling required

Image 4 shows a common lock mitre profile machined on precision moulder and end-matcher equipment. It is not recommended to use brazed carbide tooling, as profile distortion will occur during sharpening process. Profile inaccuracy will result in poor quality joinery and large gaps on the outside corner of parts, which is not an option for premium mitered products. It is highly recommended, to only use precision carbide insert or polycrystalline diamond cutting tools to ensure optimal cut quality and precise components.

Machinery required

Although Lock-mitre profile components are relatively simple in design, they can be very difficult to produce without proper equipment and precision cutting tools. The major production challenge is producing an accurate angle, and profile which will close tightly to ensure a precision joint. It is not recommended to use single spindle shaper or hand router machinery to produce lock-mitre components. The linear parts should be produced on a moulder from the side or top spindle orientation as illustrated in Image 4. Production on precision moulder equipment, is the only way to ensure accurate joinery and premium cut quality. The ends of parts need to be finished on a multi-rotational end matching machine. Single spindle shapers and router tables will not provide a high level of profile accuracy or cut quality. A multi-spindle end matcher will ensure profile accuracy and most importantly, prevent grain tearing on exit cuts.

If wood composite panel products are being used, they can be machined on a CNC router with a cutter mounted on 5-axis spindle or a moulder aggregate. This method will provide optimal efficiency and accuracy as all parts can be cut on one machine.

Critical considerations

Obviously the most important factor in any mitred product, is the visual appearance of the final exterior joint. There are several critical factors which effect final joint quality and long-term stability.

The angle of the miters is very important to ensure the joint closes properly without gaps. All joints require room for glue allowance, so a true 90 degree is not recommended. Many manufacturers use a 90.5 degree or 90.25-degree angle, to allow space for adhesive to bond both parts effectively. If there is not sufficient room for glue, it will either bleed out onto the final product creating finishing issues or create gaps in the final profile. Type of adhesive can also play a role in joint quality and function. Lock mitre joints are more stable as a function of their design, which provides additional glowing surface. Therefore, thinner glue products generally provide sufficient bonding without having a negative impact on joint quality.

Different wood species and wood composite panel products are also of critical importance. Solid wood species do have different machinability factors, which will have an impact on joinery precision prior to assembly. Varied moisture content and expansion/contraction rates will also be a factor affecting long term joint stability. Wood composite products are generally more consistent and stable in nature compared to natural wood products. However, wood composite panel products do have machineability features which need to be closely monitored. For example, plywood core products can be difficult to machine without wood grain feathering There are simply too many variables too allow for an exact recipe to be provided. But proper testing with wood materials, adhesives, and clamping methods, will provide the best chance of success.

Conclusion

Floating shelves & box stair treads provide unique style and functionality to contemporary house designs in modern home building. There are many beneficial product features which make hollow core products a viable alternative to solid wood components. However, the production process and material selection are critical to successfully manufacturing and installation. Proper machinery, cutting tool design and adhesive are all critical considerations when manufacturing precision lock-mitred products.