This is an issue within companies everywhere: “We cannot get enough workers! The new employees we are hiring do not have any experience in woodworking. The skilled workers we do have, are close to retirement age and we will face even more challenges soon.”The challenge is not new, and many initiatives are on the way: There are Red Seal apprenticeships available; multiple colleges graduating candidates, and universities in B.C. and Quebec educating people specifically for our industry. However, more people are needed than all of these organizations can produce. The government, on the federal and provincial level, is also providing funding to conduct different training programs. Industry organizations such as the Wood Manufacturing Cluster of Ontario (WMCO) and Wood Manufacturing Council (WMC), and others, are spending considerable efforts on skills development.

In my opinion, the skill level in a company can improve only if a company drives the process themselves. Skills management needs to be its own discipline in the company. It needs to be addressed in a structured and strategic manner: What do we have - what do we need - where do we get the skills from - how do we maintain/improve it – do we in/outsource. It takes almost the same strategic/structural steps when we look at developing a, let’s say, a marketing plan, equipment renewal plan or when planning the supply chain. As a critical resource it needs the highest level of management attention.

There are many methodologies out there. What is described below is a very simple process that any company can use and adjust to their specific needs.

Skills inventory –

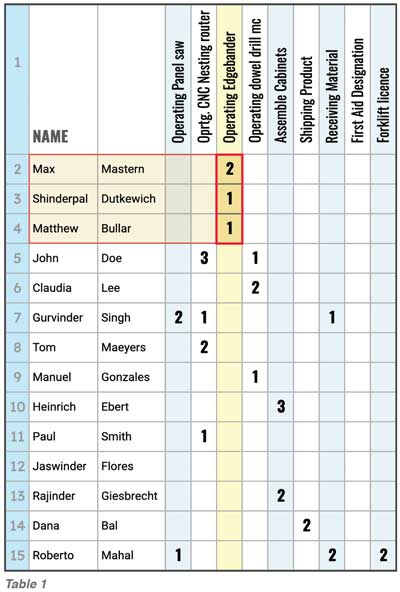

what do we have?A cross training matrix is the best approach. It can be done on a big piece of paper, but a simple Excel® sheet is the most practical approach (table 1).

The employeesOn the left side of the spreadsheet (column A), you list all the names of the employees. If your company has more than 20 persons, you also add the department and the employment start-date (year/month).

The skills categoriesOn the topline (row 1), you list all the skills. The objective is to stay practical and do not fragment it too much. For example, you can categorize: “Operate Panel Saw” or split it into “Operate Panel saw model ABC” and “Operate Panel Saw 123”. However, you do not deep dive into “Able to change Saw Blade”. The matrix will become too big and too hard to manage.

Extra skills sets, like a forklift licence, or First Aid accreditation should be listed as a skill category.

Assessment of

existing skills levelTo do this precisely would be the most complex undertaking. Simplification is the keyword here. A practical approach is a rating from 1-4. Let’s take the edgebander as the sample machine:

A skill Level 1 is a beginner. A beginner is more than an occasional helper on the edgebander. He/she knows the required safety on the machine, knows how to start up in the morning and understands the shut-down procedure to operate the machine. He/she is still required to be observed and taught/mentored by a more experienced operator or outside technician, and understands the safe and required daily cleaning process. A beginner understands how to read work instructions and identify the correct edge for the part.

A skill Level 2 is a trained operator. This operator knows how to operate the machine efficiently and is on track to do so on an ongoing basis. He/she understands the intricacies of adjusting the trimming of the edges and has a full understanding of the use of the edge magazine.

The Level 2 operator has a solid understanding of the quality expectation of edgebanding and will call for help when the required quality is not achieved. He/she understands the machine sufficiently to follow SOP and understands when maintenance input is required.

A skill Level 3 is a skilled operator. This operator understands the machine and knows how to operate this machine. Here are some to the key tasks:

- Safe and efficient operating

- Maintain the quality required

- Ensure safe working environment, especially with level 1 beginners and occasional helpers

- Conduct basic preventive maintenance routines

- Drive continuous improvement initiatives

- Understand/follow daily schedule and priorities

- Initiate maintenance requests

- Maintain edgebanding inventory

A skill Level 4 is a trainer level skilled operator. In addition to all of Level 3 skills, he/she has received appropriate “train-the-trainer” training. Understands the required SOPs and provides updates and editing to the existing SOP. He/she communicates/provides feedback and input for detailed maintenance requests and valuable input on further machine investments. He/she oversees the training for all levels below. As he/she monitors/sees the daily operation of the edgebander, he/she communicates with the supervisors where input is required.

Skills level inventoryThe level number is then documented in the spreadsheet. Note that the best worker is not automatically designated Level 4. The employee is appointed the level according to the generic skills level.

Reviewing the matrix will show you how many persons are trained on particular skills, and to what level. Often, we see that for critical jobs there is no appropriately trained person in place.

Skills planningIf your goal is, for example, to be “three-deep” on critical positions, then each critical position should have three persons graduated to at least level 2 or 3. Most companies are far from such a goal. But if you set such, or similar, goals you see the difference and you see the skills gap.

Each supervisor could have the task on their individual objectives to fill the skills gap within a given timeframe. Only when documented and assigned to a person will it have a chance of being done.

The supervisor then needs to plan on whom, how and when to train this person.

Who will be trained?One objective of the cross-training system is to enable employees to advance within the company. Nowadays companies tend to have less management levels and therefore employees have less opportunities for promotions. By having an active skills qualification program, advancements in pay can be built into this system. If there is a defined financial benefit, employees are more interested in being trained and graduating either up the skill level or train for other critical skills.

The company needs to establish how to deal with the people who want to be trained and advance. That movement needs to be funneled correctly.

Standard operating procedures

As you train people, take the opportunity to document what you are doing. If you do not have SOPs, this can be the start. And if you already have some, you can, along the training process, review and edit them as needed.

If you are new in implementing cross training, focus on a few positions to be cross trained to get experience. This will show you how much resources you need if you scale it up.

Who would be the trainer?You need to leverage the knowledge and skills already existing. The best learning is learning-by-doing. Whenever possible ensure that people are shifted around. Accept and deal with the fact that during training the productivity might suffer a bit. This means that the immediate trainers are the employees themselves.

There are also options of getting outside help. Equipment suppliers offer machine specific training. This training is usually taken when new machines are installed. Consider repeating the training. Material suppliers, for example paint suppliers or sandpaper suppliers, have a wealth of subject matter knowledge, and they are more than willing to share their experience. You just need to funnel that into your organization.

Trainers for Lean manufacturing, safety training (i.e., forklift, working at height…) quality system or management skills are often best outsourced with competent trainers.

What’s in it for

the worker?Providing training is one of the underutilized motivators for employees. It is not that we teach the operators because they do not know anything; we develop them to increase their value to the company and the labour market in general. If you spend effort in training them, you show you are interested in their development.

Inform employees about the cross-training program, explaining its purpose, benefits, and expectations. Encourage their participation and address any concerns they may have.

My suggestion is to start immediately but start small and simple. Complexity can be added as you go along.